November 9, 2023 ~ The 11,000-square-foot multi-use property features offices, warehouse space and a cleanroom/demonstration lab HILLSBORO, Ore. – November 9, 2023: ACM Research, Inc. (ACM) (NASDAQ: ACMR), a leading supplier of wafer processing solutions for semiconductor and advanced wafer-level packaging (WLP) applications, today announced the grand opening of its new multi-use facility in Hillsboro, Ore., on November 28. […] Read More

Blogs and Articles

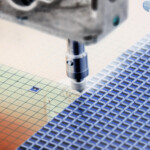

September 29, 2023 ~ Megasonic cleaning with ACM’s advanced SAPS wafer cleaning technology provides an efficient, resource-optimized solution for the complex challenges associated with photoresist (PR) removal and metal lift-off (MLO) processes in semiconductor manufacturing. In this blog, we explain how the combination of ACM’s Smart Megasonix systems, MegPie transducer, and the active puddle method delivers superior removal performance with good uniformity and particle neutrality. Learn how implementing ACM’s approach successfully cuts traditional PR and MLO process times from several hours at high temperatures to minutes at lower temperatures. Read More

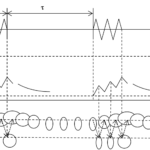

September 13, 2023 ~ In working to improve previous generations of megasonic wafer-cleaning systems, ACM discovered how to enhance megasonic uniformity across wafers with an innovative solution called Space Alternated Phase Shift (SAPS™) technology. SAPS technology outperforms conventional megasonic cleaning products and efficiently exceeds expectations beyond removing random defects. Learn more about how ACM’s unique SAPS cleaning systems enable more efficient manufacturing, reduce chemical consumption, enable time and cost savings, and increase wafer yields. Read More

July 25, 2023 ~ This article was originally featured in Silicon Semiconductor, Issue 3, 2023 Semiconductor chip features continue to shrink at a rapid pace. Dynamic random access memory (DRAM) manufacturers are now manufacturing 16GB chips in the 12nm range with an aspect ratio of 60:1 in the capacitor. NAND structures are reaching 232 layers with an even larger […] Read More

March 23, 2023 ~ What Is Electroplating or ECP? Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal using a direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte […] Read More

March 9, 2023 ~ Traditional megasonic cleaning combines high-frequency sound waves, typically in the range of 360 kHz to 2,000 kHz, with a liquid flow process to remove submicron particles from wafer surfaces. The fluid motion created by the high-frequency megasonics is intended to result in low substrate damage. However, conventional megasonic cleaning applications have reached practical limits because […] Read More

November 2, 2022 ~ Throughout this blog series, we’re examining vital wafer cleaning processes and how we are addressing them through our solutions. In this post, we’ll look at bevel etch: what it is, associated challenges, and how our approach offers notable advantages for tackling those challenges compared to traditional dry bevel etch. The bevel etch process is used […] Read More

August 31, 2022 ~ Our last blog post addressed in-depth the rise of silicon carbide (SiC)-based chips and how we address the cleaning challenges surrounding them. With their innate thinness, brittleness, and tendency toward surface inconsistencies, SiC wafers require particular care with respect to their processing and handling, and we have a broad portfolio of tools that make sure […] Read More

May 27, 2022 ~ Silicon carbide (SiC) substrate-based chips are on the (very) fast track due to SiC challenges. The automotive industry wants SiC chips so it can increase electric vehicle (EV) range and decrease charging time. The telecom industry wants them for 6G. And the renewable energy folks want them for more efficient power generation and storage. The […] Read More

June 29, 2021 ~ By Sally-Ann Henry and Jim Straus, ACM Research Let’s face it: When it comes to choosing a substrate material for building power semiconductors, silicon (Si) is no match for up-and-coming compound semiconductors like silicon carbide (SiC) and gallium nitride (GaN). Because of their fundamental material properties, these compound semiconductors can do things that simply aren’t […] Read More