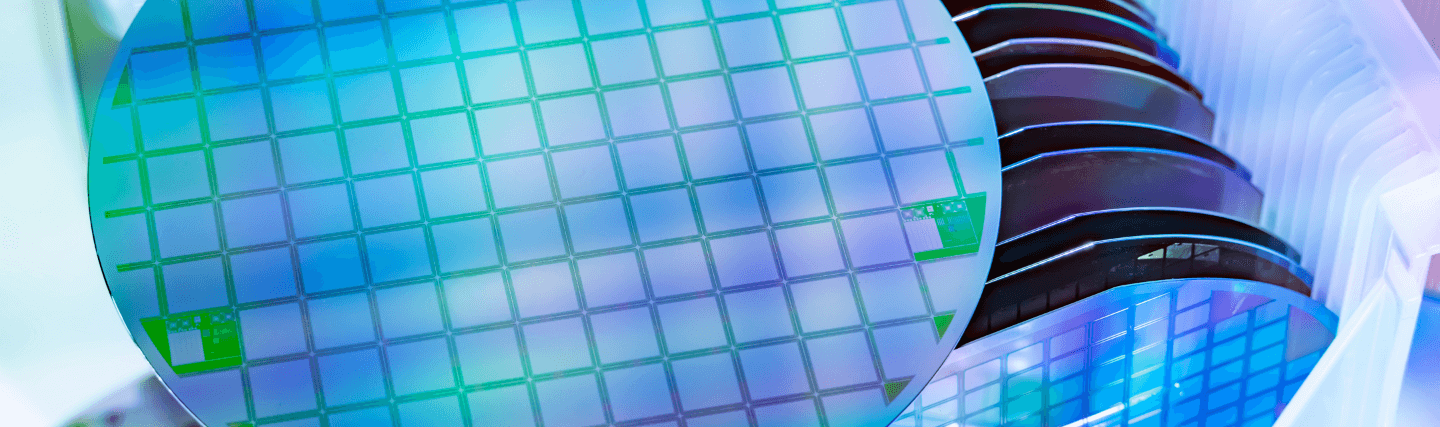

Wafer-Level Packaging

Discover How We Support Wafer-level Packaging

If you’re following the Heterogeneous Integration Roadmap, you know advanced wafer-level packaging processes are critical to improving the power, performance, area, and cost of next-generation semiconductor devices. From FOWLP and 2.5D interposers to 3D stacks and chiplet architectures, your manufacturing processes will benefit from our wafer processing expertise, customized to your requirements.

Do You Have Varied Needs for Your WLP Processes?

Our WLP offering extends beyond our leading-edge cleaning systems to support a broad spectrum of advanced WLP applications. We’ve leveraged our proprietary wet processing technology and expertise into a range of customized single-wafer tools to suit your back-end wafer assembly and packaging needs.

- Our fully automated Coater features a unique auto-clean module for ease of use

- Our flexible Developer performs three different photoresist developing methods

- Our efficient Stripper integrates batch and single-wafer processing into one system

- Our high-speed ECP plating system supports critical WLP plating steps including pillar, bump, and RDL

Because diversity is the name of the game for WLP, we accommodate your special requests and deliver custom-made, differentiated equipment that integrates multiple ACM technologies to enhance performance at a competitive price.

Plating Systems—Ultra ECP ap

Learn More

Coater Systems—Ultra C ct

Learn More

Developer Systems—Ultra C dv

Learn More

Wet Etching Systems—Ultra C we

Learn More

Wet Stripping Systems—Ultra C pr

Learn More

Cleaning Systems—Metal Lift Off

Learn More

Stress Free Polishing Systems—Ultra SFP

Learn More

Scrubber Systems—Ultra C s

Learn More

Contact Us

Looking for customized solutions for your wafer-level packaging processes?