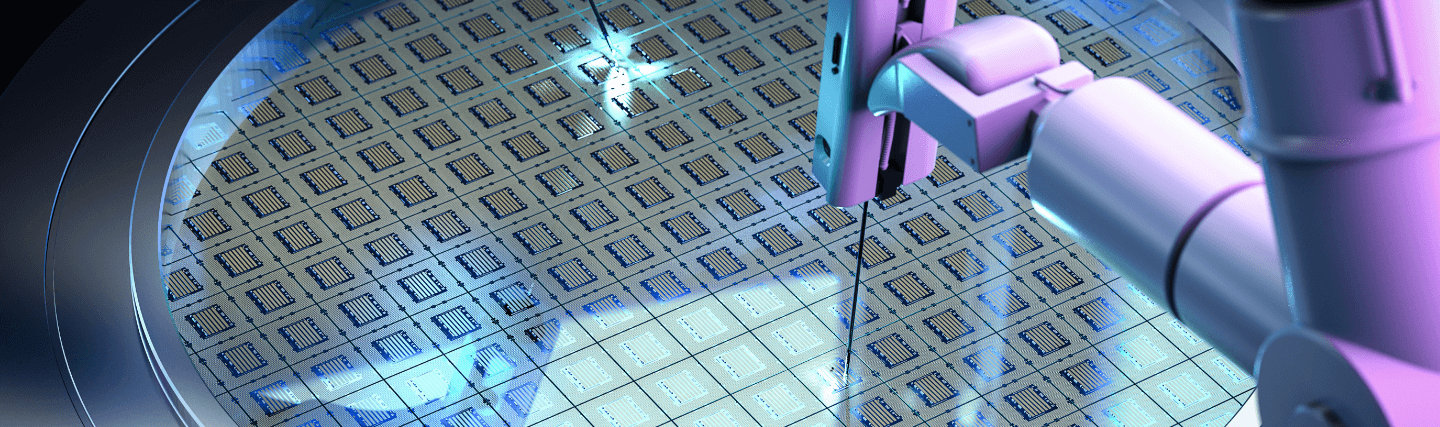

Wafer Manufacturing & Reclaim

Discover How We Support Wafer Manufacturing and Reclaim

Advanced semiconductor device manufacturing begins with manufacturing the wafers in a five-step process. Wafers are sliced from an ingot wafer, polished to a desired thickness, chemically etched to remove mechanical damage, polished using chemical mechanical planarization (CMP), and cleaned and inspected to ensure quality. Our wet bench and SAPS tools are ideal for performing all your wet processes used in wafer manufacturing, including etch, CMP, and cleans.

What is Reclaim, and Why is it Important?

Wafer reclaim removes deposited films from blanket wafers so you can use them again. If you use “dummy” wafers to test processes, you understand what a costly exercise this can be, especially if the test wafers fail. Rather than disposing of these wafers or shipping them out to an expensive reclaim service, why not reclaim them in-house?

By using traditional process chemistries in a dedicated tool, configured with high-concentration formulations, you can strip test films from test wafers and reuse them several times before disposing of them. In-house reclaim allows you to reuse wafers immediately, saving you time and money. It also helps you on your path to sustainability. At ACM Research, all our wet benches and our SAPS tools can be configured specifically for wafer reclaim.

Cleaning Systems—Ultra C SAPS

Learn More

Cleaning Systems—Post CMP Clean

Learn More

Cleaning Systems—Ultra C wb

Learn More

Contact Us

Looking for customized solutions for your wet wafer processing, ECP, Furnace, Track and SFP?