Cleaning Systems—Single Hot SPM

Discover the benefits of Hot SPM

In IC manufacturing, sulfuric peroxide mixture (SPM) process steps are widely used for photoresist stripping post-etch, post-implant and post-CMP processing. Traditionally, these processes were performed at temperatures below 145°C. Technology nodes at 28nm and beyond need higher dose ion implantation, which hardens the photoresist. Hot SPM processes at temperatures of up to 200°C are necessary to effectively remove defects. Additionally, wet stripping without using a dry ash process, and special metal film removal processes all require higher-temperature SPM.

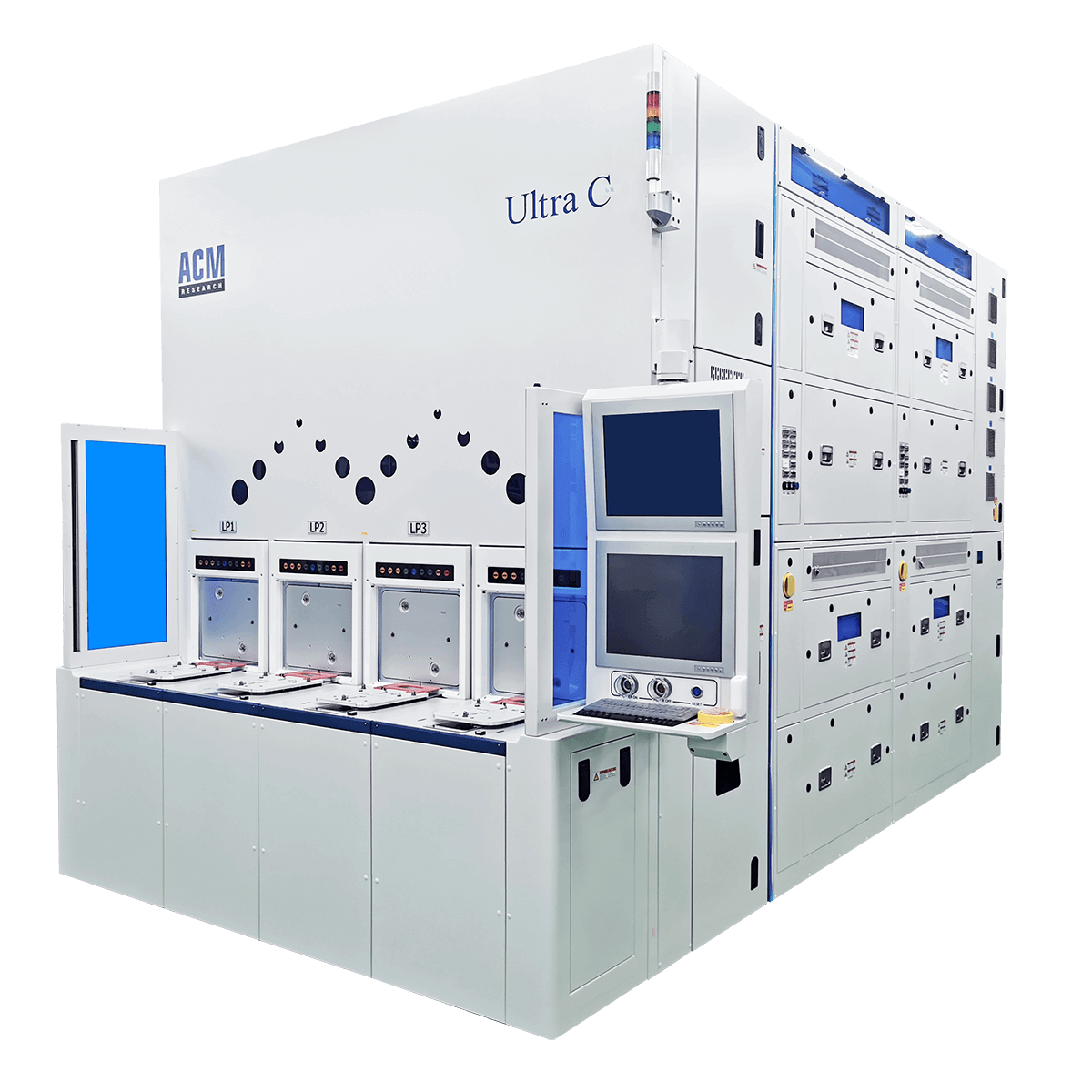

We designed our Single Hot SPM tool to meet your advanced SPM process needs. The platform also supports, SC1, SC2, DHF, hot DIW, DICO2 and DIW as well as IPA for drying. The Hot SPM tool is configured to support higher temperatures and shorter process times. It achieves organic defect removal with less film loss than most post-clean and PR wet strip processes.

Major Benefits

- Preheats sulfuric acid before mixing with hydrogen peroxide to achieve super high temperatures.

- Dynamically sets chemical mixing ratio and temperature.

- Configurable based on customer requirements.

- Supports standard thickness 300mm wafers.

Features and Specifications

- Multilevel gradient heating system

- Chemical in-line mix (CIM) system

- Mechanical chuck

- Index Robot with 4 ceramic robot arms

- Process Robot with four ceramic robot arms

- TEBO™ Megasonix™

- SAPS™ Megasonix

- Advanced IPA drying

- 12” load port

- 8-12 SPM Chambers

- N2, Spin dry, IPA dry

- Clean chemistries include: DHF, SC1 , SC2 , SPM, DICO2 N2, IPA

- Achieves etch uniformity of <2%, DHF@TOX