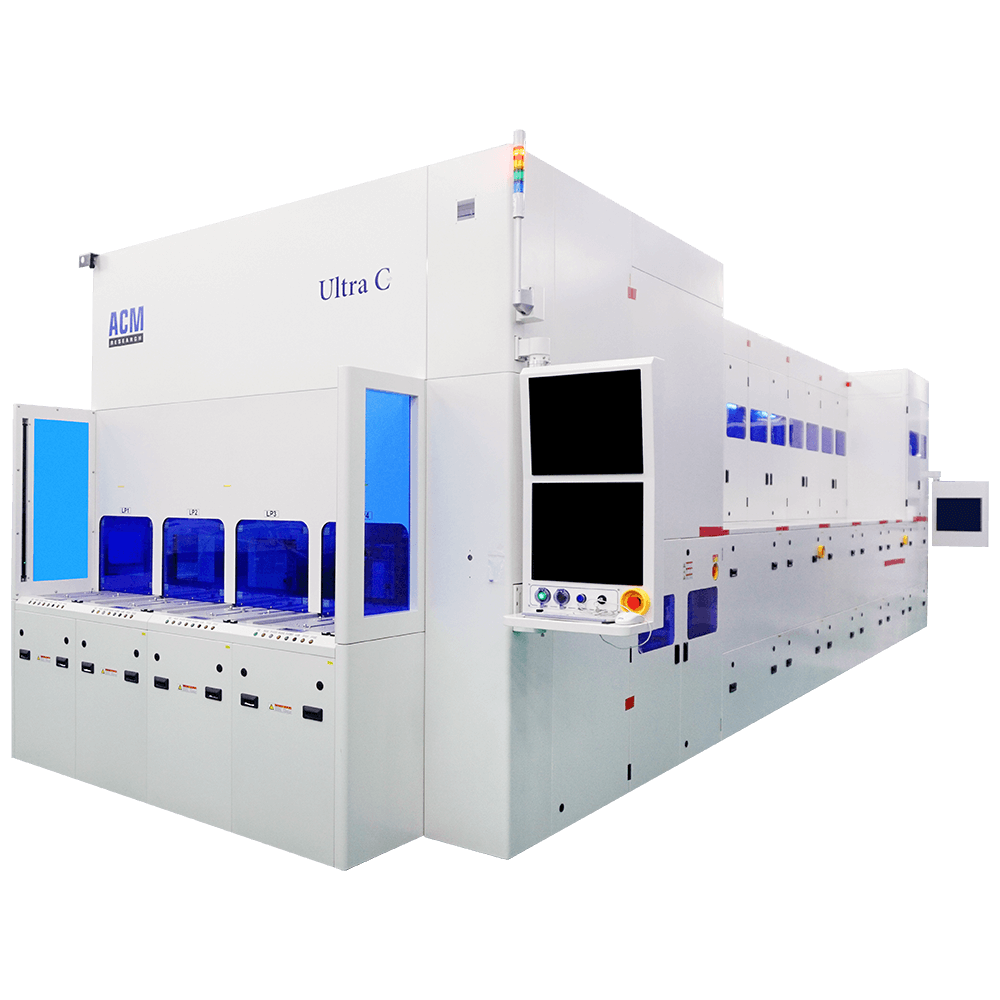

Cleaning Systems—Ultra C wb

For advanced technology wet batch cleaning processes

High Throughput, eco-friendly wet cleaning technology

“Ultra C” stands for “Ultra Clean,” and wb stands for “Wet Bench.” The Ultra C wb is an environmentally friendly system due to reduced process times and less chemical waste compared to single wafer wet clean equipment.

The Ultra C wb system can run various chemical cleaning (SPM / DHF / HNO3 / HF / SC1 / SC2 / H3PO4). Unlike single wafer tools that clean by spraying chemicals on the wafer, batch tools reuse the chemicals through re-circulation/filtration that reduces both chemical and post-treatment waste disposal costs. This tool is designed for 200mm or 300mm wafer wet batch processes widely used in IC wafer manufacturing.

Batch processing is still a good choice for even advanced node applications

Conventional wet cleaning is performed in a wet bench tool using various chemicals to remove unwanted materials from wafers during the various process steps: strip (nitride, poly, oxide, metal, photoresist); post-etch clean; post-implant clean; and post CMP clean processes.

The Ultra C wb uses an optimized batch system for cleaning process steps, and can be used for PR strip, dummy strip (nitride, poly, oxide, metal) post-etch clean, post-implant clean, post-CMP clean, and even pre-dep clean by improved tool configurations and recipes.

In our cassette-less system, wafers are cleaned in tanks and include processes such as SPM, quick dump rinse (QDR), standard RCA cleaning processes, or other process chemicals. Another method is to use a multi clean and rinse (MCR) bath where chemical cleaning and deionized water (DIW) overflow rinse can be used in one bath. After DIW rinse, an ATOMO dryer with vaporized isopropyl alcohol (IPA) is also integrated into the tool. There is another option to improve the cleaning with the SC1 and SC2 megasonic functions.

Ultra C wb cleaning applications

The Ultra C wb is the proven solution for wet batch cleaning applications, including:

- SPM photoresist stripping

- Pre furnace cleans

- Post etch cleans

- Post IMP cleans

- Post CMP cleans

- Nitride Removal

- Oxide Etch

- Wafer Reclaim strip (Nitride, Poly, Oxide, Metal)

Major Benefits

Proven processes

The Ultra C wb is a system that reduces the relatively long times for removing particles from fine features. With the independent processing modules, advanced drying module, precise cleaning and rinsing flow control, it delivers high cleaning performance and eliminates cross-contamination.

Lower costs

With a precise chemical circulation system, the Ultra C wb delivers low chemical consumption and therefore savings of chemical costs as well as waste treatment costs.

Features & Specifications

- Reduced cross-contamination risk with face to face EFEM option

- Excellent film strip removal

- Achieves high throughput of 350 wafers per hour for typical PR strip processes

- 300mm and 200mm wafer compatibility

- Cassette-less wafer handling

- Currently qualified at 60nm

- Customized and configured to customer specification

- Options include:

- IPA dry

- Multi Clean & Rinse bath (MCR)

- Proven Megasonic bath

- Chemistry option

- Sulfuric Peroxide Mixture (SPM)

- Standard Clean 1 (SC1)

- Standard Clean 2 (SC2)

- Hydrofluoric acid (HF)

- HNO3/HFmixture

- Buffered Oxide Etch (BOE)

- Phosphoric acid (H3PO4)

- Other process chemicals

Contact Us

Looking for customized solutions for your wet wafer processing, ECP, Furnace, Track and SFP?